Metallography

Introduction

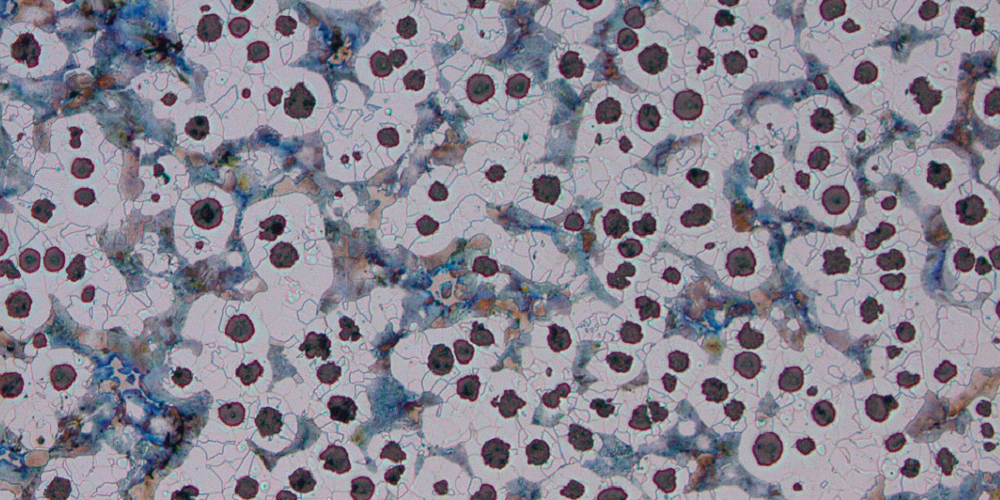

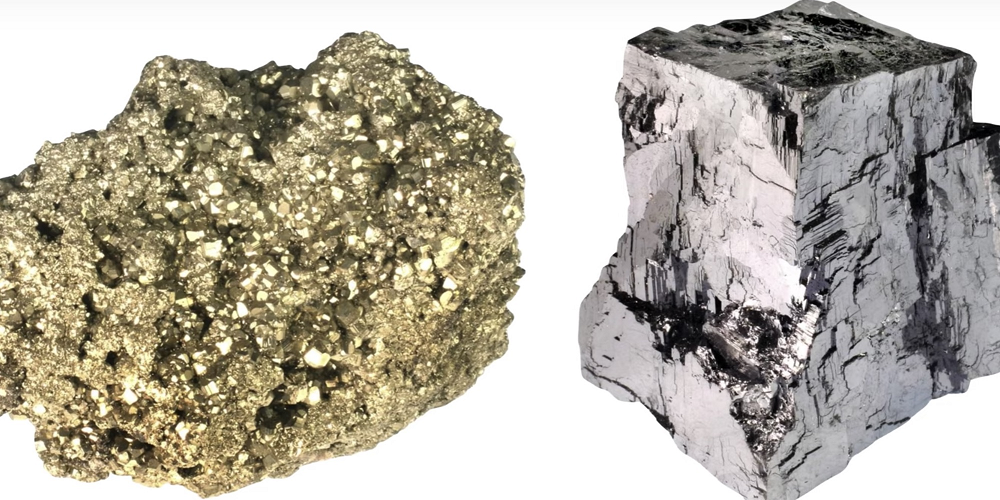

Metallography involves the procedures required to view the internal micro structure of a metal. The properties of engineering materials that are in everyday use are dependent on the compositions of the materials that are used in making them. In …