Introduction

“Cheese” as a word comes from the Latin word caseus from which the modern word casein is also derived. Hence; Cheese is a food derived from milk that is produced in a wide range of flavours, textures, and forms by coagulation of the milk protein (casein). It comprises proteins and fats from milk, usually the milk of cows, buffalos, goats, or sheep. During production, the milk is usually acidified, and adding the enzyme rennet causes coagulation. The solid are separated and pressed into final form.

Some cheeses have molds on the rind, the outer layer, or throughout. Most cheese melt at cooking temperature. Hundreds of types of cheese from various countries are produced. Their styles, textures and flavors depend on the origin of milk (including animal’s diet), whether they have the pasteurized, the butterfat content, the bacteria and the mold, the processing and age of the animals’ milk that is being used. Herbs, spices or wood smoke may be used as flavoring agents. The yellow to red colour of many cheese, such as annatto (an orange-red condiment and food coloring derived from the seeds of achiote tree) it often used to impact a yellow or orange colour, but mostly for its flavour and aroma. Other ingredients may be added to some cheeses, such as black pepper, garlic, chives or cranberries.

For a few cheeses, the milk is curdled by adding acids such as vinegar or lemon juice. Most cheeses are acidified to a lesser degree by bacteria, which turn milk sugars into lactic acid, and then the addition of rennet completes the curdling. Vegetarian alternatives to rennet are available; most are produced by fermentation of the fungus (Mucur miehei), but others have been extracted from various species of the cynara thistle family. Cheese makers near a dairy region may benefit from freshness, lower-price, and lower shipping costs of milk. Cheese is valued for its portability, long life, and high content of fat, protein, calcium, and phosphorus. Cheese is more compact and has a longer shelf life than milk, although how a cheese will keep depends on the types of cheese; labels on the packets of cheese often claim that a cheese should be consumed within three to five days of opening. Generally, hard cheeses such as parmesan last longer than soft cheese, such as brie or goat’s milk cheese. The longer storage life of some cheeses, especially when encased in a protective rind, allows selling when markets are favourable.

There are some debates as to the best way to store cheese, but some experts say that wrapping it in cheese paper provides optimal results. A specialize seller of cheese is known as cheese-monger. The cheese-monger is responsible for all aspects of the cheese inventory: selection of cheese making venue, determination of the milk source, storage and processing.

Breed of Cattle used for the Milk Extraction

Generally, there are various breeds of the cattle that is being rear in this geographical part of the world, most of the breeds rear by Fulanis are; Wadara, Bunaji (white Fulani), Rahaji, Sokoto Gudali, Azawak, Adamawa Gudali, etc; But the breed that will be discussed here for milk extraction is the white Fulani breed (bunaji) shown in Fig. 1.

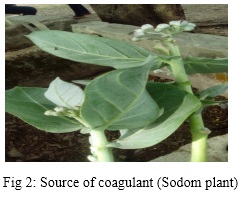

Vegetable Rennet

This is a coagulant that releases enzyme which aids the conversion of milk sugar (lactose) into lactic acid (Fig. 2). Any part of sodom plant such as leaves, stems or fruits can be used as rennet for curdling milk in cheese production. The enzyme extracted from any part of sodom herbs, stem or fruit is capable of acting upon the milk’s proteins getting them to clump together as semi-solids (curd), and separate the clump portion from the liquid (whey). Both the leaves and the stem can be used. In other word; one can combine any of the two, or the three parts of the sodom plant in a suitable form and in the right proportion in a situation where the supply of one is not enough.

NB: it is important to know that addition of rennet was the first step in cheese making process after the milk extraction, and it serves the purpose of curdling the milk and also it helps in coagulaton of casine in it.

Objective(s) of the Experiment

This process is carried out to extract milk from cattle and convert the extraction to cheese

Equipments and Materials Neede

• A Rope: This was used to tie the neck of calves to their mother’s leg in order to allow milk extracion.

• A coverd bowl: This is where the milk collected is being stored temporarilly.

• Vegetable rennet commonly known as sodom juice • A sieve

• A tray for covering the cheese from flies • Molders (Fig. 3)

• One long-handle plastic spoon

• A bowl to put the sieve upon

Procedures

Process of Milk Extraction

• The calf of the selected cow should be persuaded to go for milk sucking from the mother. This is done so as to hasten the down flow of milk from the udder of the nursing mother.

• One minute after the commencement of the milk sucking, the calf should be sent away from the position of the udder by tying the neck to one of the fore-legs of the mother. This will give the opportunity and access for easy extraction of milk (using hand) from the nursing mother of the deprived calf (as shown in Fig. 4).

• After the milk had been successfully extracted, the rope is untied from both the calf and the nursing mother.

• This same principle is employed for the subsequence nursing cows and their calves in order to make the milk extraction easy, convinient and successful without any form of hinderance or disturbance from the nursing calves.

Process of Cheese Productionn

1. After the extraction, pour the freshly extracted milk into a big cooking pot that has the capacity of holding ten litres of milk.

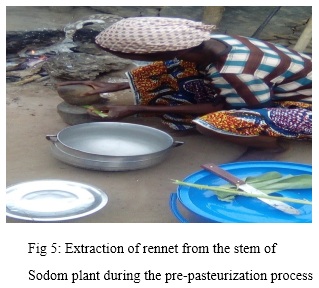

2. Add some little quantity of vegetable rennet commonly known as sodom juice that is squeesed from some parts (stem and leaves) of sodom plant as shown in Fig. 5 and should be added to the milk.

3. Immediately after the squeezed leaves and the stem had been put inside the milk in the pot, stir the mixture together. This is done so as to allow effective dissolution of the rennet inside the milk.

4. About five minutes after doing this, the chaffs and the unwanted part of the coagulants should be sieved away.

5. Put the milk solution on fire for coagulation to take place. The pot on the fire containing milk is to be covered partially and while this pot is on fire, the milk should not be stirred at all. Although, covering the milk or not, does not make any difference, it depends on the knowledge, expertise level and the style of the maker. Also the reason for boiling is that it will aid pasteurization by heating up of the milk to kill any harmful bacteria or viruses in the mixture, and also for faster coagulation to take place. This heating process should last for about 20 minutes.

6. After the 20 minutes, remove the pot’s lid from the pot. The result is confirmed by the formation of scaly substance known as junket on the top layer.

7. Subsequently, make all the baking utensils ready this includes: a sieve, a tray for covering the cheese from flies, molders, one long-handle plastic spoon, and a bowl to put the sieve upon. All these are used to make sorting out of cheese easy and conveniently done.

Notes

It should be observed that cheese has three layers:

• Junket: This is the upper layer of the cheese, when cheese is being freshly remove from the fire it is easily noticeable, it looks like scalp. This layer is not consumable

• Curd: This is the semi-solid part of the cheese after milk has been coagulated. It is the most consumable part of cheese, and it is widely acceptable by the general public.

• Whey: This is the watery part of cheese. It is also consumable but not generally acceptable by the general public.

Sorting Out Process of Cheese

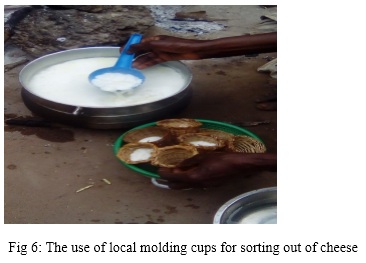

1. After the heating, African molding cups which looks like small baskets (refer to Fig. 3) will be used to sort out the cheese. This is done by scooping the coagulated cheese (both the semi-solid and the liquid portion) together into the molding cup. This is a continuous sequence from the first molder to the second, to the third molder until all the molders was filled (shown in Figure 6). The serving purpose of the mold is that it gives an accurate, uniform, and attractive shapes to the cheese.

2. After about five minutes, the curds will be formed by being partially solidified i.e. becoming semi-solid whereby the liquid portion (whey) should get settled below the molds that was put inside a bowl, and the curd remained firm inside the molders, then the curd should be turn into a clean container for consumption or for the cheese- mongers for marketing operation. This whole process is repeated until the cheese is finished from the pot.

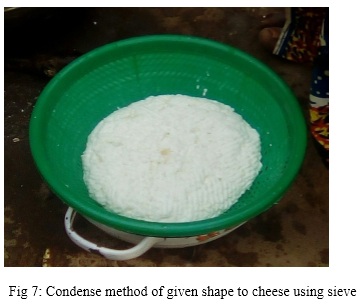

3. Apart from the traditional cheese molders which happen to be one of the methods used to package and give shapes to cheese, it should be noted that a sieve can as well be used due to the fact that it saves time of scooping the coagulated cheese into the cheese molders one after the other. In other words, sieve has a larger capacity of holding and sorting out of cheese than the molding cups. One of the advantages of the sieve is that it have the capacity of filtering or separating the whey from the curd (Fig. 7).

4. From the condense form of molding cheese, Understand that after it has been sorted out like this, by separating curds from the whey, cheese can be cut with knife into different sizes. Although, the method of using sieve is not widely practiced by the local cheese sellers due to the fact that they are still operating under a conventional system.

Conclusion

Benefits of Cheese

• Cheese making provides source of employment for people especially, the rural dwellers that are in dairy region e.g. Fulani women

• It serves as source of income

• Cheese provide cheap source of protein to aid growth and repair body cell.

• It is a source of calcium for strong bone and teeth.

• It promote growth and weight gain because it is highly proteinaceous.

• Cheese is more compact and have high self-life than milk

Download “Cheese Making Report”

Download “Cheese Making Procedure”