Introduction

Heat treatment is the process of heating or chilling a material usually at extreme temperatures in order to achieve the hardening or softening of the material. It involves heating the material up to austenizing temperature and then allowing it to cool at a specific rate. Materials consists of microstructure called grains or crystallites. The nature of the grains (i.e. the grain size and composition) is one of the most effective factors that can determine the overall mechanical behaviour of materials. Heat treatment provides an efficient way of manipulating the properties of metals by controlling the rate of diffusion and the rate of cooling within the micro-structure. The mechanical properties often being manipulated by heat treatment include: hardness, ductility, strength, toughness, elasticity, etc.

There are two mechanisms that may change the properties of the alloy during heat treatment, they include:

1. The formation of martensite causes crystals to deform intrinsically

2. The diffusion mechanism causes change in the homogeneity of the alloy.

Crystals in the lattice tend to rearrange themselves if external factors such as temperature, pressure are increases drastically. This rearrangement is what is referred to as allotropy or polymorphism, and it may occur several times in a material depending on the temperature. The different types of heat treatment that we have include: Annealing, Normalizing, tempering, hardening as discussed below:

• Annealing: This is the process of heating a metal to its austenizing temperature and then leaving it in the furnace to cool. The cooling rate of the material is controlled by the cooling rate of the furnace which in turn relieves the internal stresses of the material and makes them soft, ductile and workable.

• Normalizing: This is the process of heating a material to its austenizing temperature and allowing it to cool slowly in air. The cooling rate is controlled by the room temperature of the environment in which it is being cooled.

• Tempering: This is the process of heating a metal to its austenizing temperature and then quenching it in a medium and then heating back again to about 450o c.

• Hardening: This is the process of heating a material to its austenizing temperature and then quenching it in a liquid medium. The liquid medium could be water, mineral oil, ash, etc. The cooling rate of the material is determined by the nature of the quenchant being used. Hardening a material makes the material very brittle and less ideal for tensile loadings.

Objective of the Experiment

This experiment is done to study the effect of heat treatment on steel specimens

Equipments Needed

1. Electric arc furnace

2. Venier calliper

3. Tensometer.

Procedures

1. Take the sample to an electric arc furnace and heat to about 912oC.

2. After getting to this austenizing temperature, leave the sample at this temperature for 30 minutes in order to choke it at this temperature. The aim of choking is to make sure that the temperature is uniform throughout the sample in order not to give variation in result.

3. After choking for 30 minutes, quench the sample in water and leave till the next day for it to cool off properly before the other tests are carried out.

4. After cooling off, carry out mechanical tests on the sample. And these mechanical tests include: Hardness and Tensile test. A control sample should be attained in order to compare the results we get on the heat treated sample with that of the control sample. The control sample is the sample that has not being worked upon.

5. Carry out the mechanical properties (both the tensile and hardness) tests on the Tensometer.

6. In order to carry out the tensile test, fix the sample on the tensometer with everything in place and load it with a 1000Kgf, until fracture.

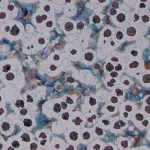

7. In order to carry out the hardness test, grind the broken edge of the sample and polish till a mirror like surface is achieved and then fix it on the tensometer and load with a 750Kgf. After loading, leave it at the spot for 15 seconds in order for the grain to settle in and for the indentation to be visible. Hardness test like the Brihnell’s hardness test is carried out on the heat treated sample. After the indentation, use a Brihnell microscope to measure the diameter of the indentation.

Results and Calculations

The results from the experiment is tabulated as shown below:

1. Results from Tensile Test

Where

Lo = Initial length

Lf = Final length

△L = Change in length = Lf – Lo

Do = Initial diameter

Df = Final diameter

Ao = Initial cross sectional area

Af = Final cross sectional area

2. Results from Hardness Test

The following parameters should be calculated on the specimens:

Tensile stress = Load/Area (kgf/cm2)

Tensile strain = (△L )/Lo

Young’s Modulus, E = Stress / Strain

Yield stress, which can be calculated by 0.2 percent offset rule, which assumes that the yield stress is 0.2 percent of E. That is Yield Stress = 0.002 x E

Total reduction in area = (Ao – Af) / Ao

Discussion and Conclusion

The tensile strength, yield strength, and hardness of the heat-treated specimen and that of the control sample should both compared to determine the effect of heat treatment on the steel material.

Generally, the tensile strength, yield strength, and hardness of annealed steel is increased plastically while the impact strength and ductility decreased due to strain hardening effect.

The normalized sample also increases in tensile strength, and has an even higher hardness than the annealed. It is required for final treatment of manufacturing.

Tempered sample gives an increased tensile strength and hardness compared to the control sample as a result of the formation of martensite and ferrite structures obtained.

Hardened sample has the highest hardness rating but the lowest tensile strength. It also has a very high compressive strength because of the formation of martensite.

From the results obtained, it can said that mechanical properties depends largely upon the various form of heat treatment operations and cooling rate. Hence, depending upon the properties and applications that maybe required for any design purpose, a suitable heat treatment should be adopted.

Download “Heat Treatment - Procedure”

Download “Heat Treatment - Report”