Introduction

For power to be transmitted from one machine to another over a distance there is need for a transmission mechanism. Therefore, mechanical drives are mechanism which is intended to transmit mechanical power over a certain distance usually involving a change in speed and torque. For this to happen there is need for a prime mover called the driver such like electric motor and a machine to be driven, such as threshers, grinding machine, extractors, de-hullers to mention but a few.

Types of mechanical drives

There are three major types of mechanical drives that are used to transmit power

a. Belt

b. Gear

c. Chains

Classification of mechanical drives: mechanical drives are classified according to the principles of operation which include the following:

1. Mechanical drives that transmit power by means of friction e.g. belt and rope drive

2. Mechanical drives that transmit power by means of engagement, e.g. chain and gear drives.

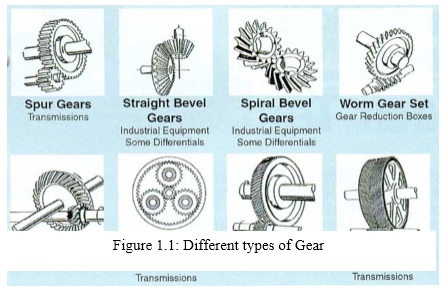

Gears

Gears are toothed members which transmit power / motion between two shafts by meshing without any slip. Hence, gear drives are also called positive drives. In any pair of gears, the smaller one is called pinion and the larger one is called gear immaterial of which is driving the other. When pinion is the driver, it results in step down drive in which the output speed decreases and the torque increases. On the other hand, when the gear is the driver, it results in step up drive in which the output speed increases and the torque decreases

The picture below will show the list of types of gears that are available. More material will be uploaded for reference purpose.

Belts

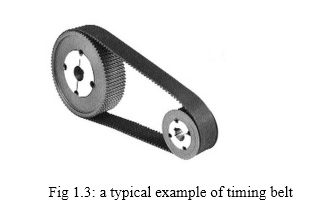

Belts are transmission device used to connect two pulleys together to transmit power between two shafts. We have different types of belt but the common ones are the V-belt and flat belt (fig 1.2), we also have another type of belt called the timing belt. (fig 3)

Chains

Description: A chain drive consist of an endless chain whose links meshed with a toothed wheels called sprockets which are keyed to the shafts of the driver and driven mechanism. Precision chains, of which roller chains and silent chains are example that is made up of parts that are finished to close tolerances. They are engaging the teeth sprockets wheels which are manufactured to equally precise standards and provide smooth, efficient operation. We have the roller chains and silent chains.

Download “Introduction to Mechanical and Transmission Drives”

Introduction-to-Mechanical-and-Transmission-Drives.docx – Downloaded 0 times – 378.03 KB