Introduction

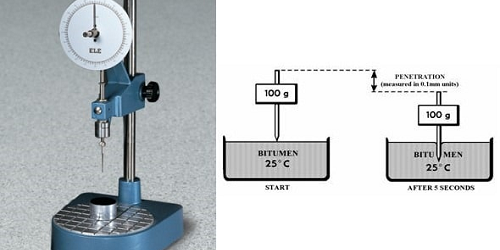

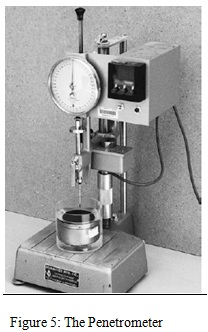

The penetration test is an empirical test used to measure the consistency of asphalt cement. Generally, the penetration of a bituminous substance may be defined as the distance in hundredths to which a standard needle penetrates the material under known conditions of time, loading and temperature. This test is used for evaluating the consistency of asphalt material before and after heating.

Objective(s) of the Experiment

The test is carried out to determine the penetration of semisolid and solid bituminous materials.

Equipments and Materials Needed

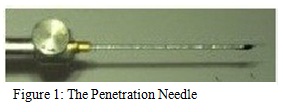

- Penetration apparatus and needle

- Sample container

- Water bath

- Transfer dish

- Timing device for hand-operated penetrometers

- Thermometers

Procedures

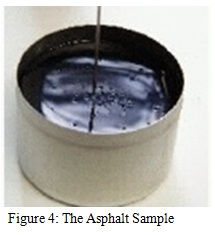

- Heat the asphalt binder sample until it has become fluid enough to pour.

- Pour the sample into the sample container and let it cool for at least 1 hour.

- Place the sample, together with the transfer dish in the water bath at a temperature of 25°C (77°F) for 1 hour to 2 hours.

- Clean and dry the needle with a clean cloth, and insert the needle into the penetrometer. Unless otherwise specified, place the 50-g mass above the needle, making the total moving load 100 g.

- Place the sample container in the transfer dish, cover the container completely with water from the constant temperature bath, and place the transfer dish on the stand of the penetrometer.

- Position the needle by slowly lowering it until its tip just makes contact with the surface of the sample. This is accomplished by bringing the actual needle tip into contact with its image reflected by the surface of the sample from a properly placed source of light.

- Quickly release the needle holder for the specified period of time (5 seconds) and adjust the instrument to measure the distance penetrated in tenths of a millimeter.

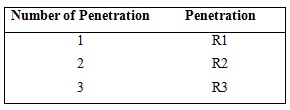

- Make at least three determinations at points on the surface of the sample not less than 10 mm from the side of the container and not less than 10 mm apart.

Results and Calculations

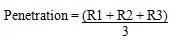

Report the average of the three penetration values to the nearest whole unit as shown in the table below:

Precautions and Instructions

- There should be no movement of the container while needle penetrates into sample.

- The sample should be free from any extraneous matter.

- The needle should be cleaned with benzene and dried before penetration.

- Type of needle to be used is brass

Conclusion

Penetration test is a commonly adopted test on asphalt to grade the material in terms of its hardness. An 80/100 grade bitumen indicates that its penetration value lies between 80 & 100. Grading of asphalt helps to assess its suitability in different climatic conditions and types of construction. Higher penetration grades like 180/200 are used in colder regions to prevent the occurrence of excessive brittleness. High penetration grade is used in spray application works.

References

- Scribd. “Penetration Test”. htttp//www.scribd.com/doc/86556621/Penetration-Test#. Assessed on February 28, 2018.

- Mamlouk, M.S. And Zaniewski J.P. (2011). “Materials For Civil and Construction Engineers”.

Download “Penetration Test of Asphaltic Cement”

Penetration-Test-of-Asphalt-Cement.docx – Downloaded 0 times – 332.02 KB