Introduction

“Seasoned Timber” is a common term and/or materials we encounter from day to day timber. From childhood days wooden cots and toys, to school desks and, eventually, to wooden furniture and flooring in homes or places of employment – seasoned timber is to be found. Yet how many people really understand what seasoned timber is? It is to be regretted that even some people associated with the timber trade have little knowledge of what seasoned timber is and the best method of obtaining it.

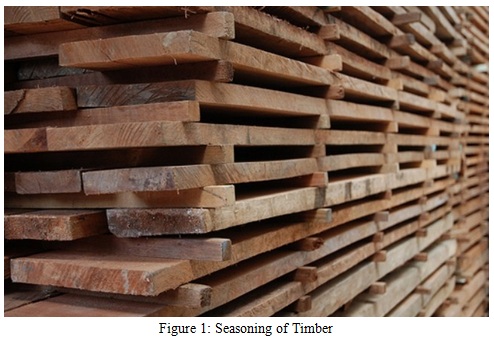

What is Seasoning of Timber?

The process of drying out the water from “wet” or “green” timber is termed “seasoning”, or more simply “drying”. Water is just as essential to the life of a tree as it is for all living matter. Together with the various minerals, it enters through the roots of the tree and is carried in the sapwood – the outer woody part to the leaves. The food, that is the sugars and starch, are made in the leaves by photosynthesis and are transported in solution down the inner bark to the growing cells. The whole trunk of the tree is made up of cells, which are like small tubes, having walls of cellulose and a more or less hollow’ cavity filled with water and other materials known as sap. Consequently, when the tree is felled and the resulting log is sawn into timber, the sawn sections consist of innumerable small cells containing water. Drying the moisture out of wood enhances its properties to such an extent that the resulting timber is given the special name “seasoned” rather than “dried” although the terms are identical.

Thus, Timber seasoning is the process of drying the timber out to bring it to a usable and workable condition. More than half the weight of freshly cut timber consists of moisture or sap. Before the timber can be used a large part of the moisture must be removed.

Reasons for Timber Seasoning?

- To prevent shrinkage, splitting, checking and warping.

- To achieve greater stiffness and strength.

- To allow penetration of preservatives

- To obtain a surface that will accept paint, polish or glue.

- To protect against decay.

Moisture Content of Timber

In order to understand what is meant by seasoned timber the term “moisture content” must be understood. This is simply the weight of water contained in a piece of timber compared with the weight of actual woody substance in the same piece. This is usually expressed as a percentage as shown below.

The green moisture content, that is the moisture content of a freshly sawn log, varies with the density of timber. Balsa, a very light porous timber, can have a green moisture content of 400 per cent, but ironbark, a very heavy timber, has a green moisture content of only about 40 per cent. In iron bark, there is so much woody tissue that there is very little free space to hold water. This water not only is contained in the hollow spaces in the woody cells (i.e. in the cell cavities) but also saturates the walls of the cells.

Therefore, water is stored in wood in two main forms:

- As free water in the vessels and/or cells, used to move nutrients within the tree.

- As cell (or bound) water, which is an integral part of the cell walls.

Initial seasoning first removes the free water contained from within the cells to a moisture content of 25 to 35 percent. The cell walls still contain moisture. This state is known as the fibre saturation point.

With further seasoning, the combined moisture within the walls of the cells begins to dry out and the cells and timber begin to shrink, so this part of the process must be carried out with careful control over drying rate.

The equilibrium moisture content (EMC) is the moisture content at which the wood is neither gaining nor losing moisture, usually 12-15%; this however, is a dynamic equilibrium and changes with relative humidity and temperature.

Methods of Seasoning

A. Natural Seasoning

1. Air Seasoning.

The timber is stacked on foundations to keep it off the ground. Strips of wood (about 38 x 19 mm) are placed between the layers of boards to allow air to circulate. Ends of boards may be painted to retard drying and prevent splitting. A waterproof covering is placed over the stack to protect the timber from the sun and the weather.

Air seasoning is slow, and may take up to a year for a piece 25 mm thick and considerably longer for thicker pieces. But the timber produced is well suited to outdoor work.

2. Water Seasoning.

This method is used to speed up the seasoning process. The logs of timber are left in the river to float down the river to the saw mill. The water passes through the porous part of the logs and removes the sap. Afterwards, the logs are cut into sections as described in air seasoning and allowed to dry.

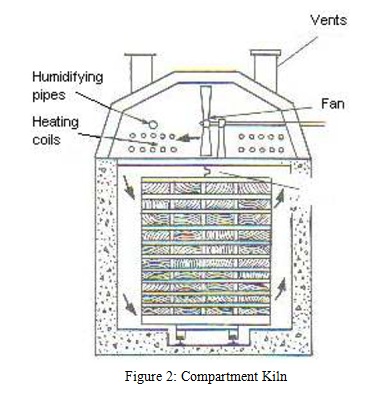

B. Kiln Seasoning (Artificial Seasoning)

Kiln seasoning is done in a large oven-like structure in which air circulation, humidity and temperatures are controlled. The timber is stacked on the trucks in the same way as for air drying. The trucks are on rails so that they can be moved into the kiln. Care must be taken to see that the drying process while removing the free water is not too rapid, as at this stage the timber is susceptible to degrade (damage) by checking and collapse.

Many types of softwood, such as Radiata Pine, can be kiln dried easily and fairly cheaply from the green condition. But many of the Australian hardwoods are so slow in drying that their kiln drying is uneconomical. It is, however, satisfactory and economic to season them by the combined process of air and kiln drying mentioned below.

Types of Seasoning Kilns

1. Compartment Kilns.

Circulation is induced by fans forcing air over heating coils and humidifying sprays and through the timber stack. The fans are reversible to allow uniform seasoning on each side of the stack. Kiln conditions are uniform and can be regulated to suit the stage of seasoning.

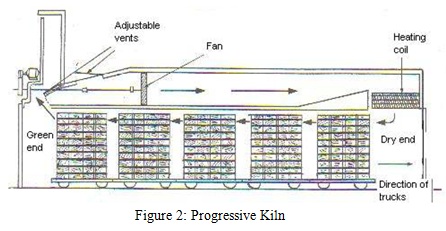

2. Progressive Kilns.

In this type of kiln the conditions at one end of the kiln differ from those at the other end. An unbroken line of trucks, all at different stages of drying, extends through the kiln. As a truck of green timber enters at the cool, moist end, another is removed from the hot, dry end ready for use; the drying process is continuous.

Heated air is circulated by fans along the kiln from the hotter and drier end to the cooler and moister end. As it passes through the timber it gradually cools and picks up moisture, thus, the drying conditions at the greener end are less than those at the dry end.

C. Combined Seasoning

- The timber is first air dried for several months, the actual time depending on the species of timber, thickness and climate. The slow air drying, until the free moisture has been removed (i.e., to fibre saturation point – 25-30% M.C.) reduces the tendency to degrade by warping, checking and collapsing.

- The timber is then kiln dried to remove the combined moisture from the cell walls to the required moisture content. This can be done rapidly in several days to a week or so.

Notes

- The moisture should be extracted during seasoning under controlled conditions as nearly as possible at a uniform rate from all parts of the timber.

- The moisture which cannot be extracted during seasoning is uniformly distributed throughout the mass. If the drying is irregular, the shrinkage of timber will also be irregular and it will set up internal stresses between the fibres. When these stresses become excessive and are capable of overcoming the cohesion of fibres, the timber warps and the shakes are formed.

- The wood is a hygroscopic material. The capacity of wood to absorb water vapours from air is called hygroscopicity of wood. The dry wood absorbs the moisture from the surrounding air. Now, the air humidity is not constant and hence the wood moisture content also varies accordingly. The fluctuations in wood moisture content from zero to fibre saturation point cause corresponding volume changes in wood leading to cracking, warping, swelling and shrinkage of wood.

- By the process of seasoning, the excess water of timber is extracted in such a way that the moisture content of seasoned timber corresponds to the required moisture content of timber for the environments in which it is to be used.

- Seasoned timber should be protected from exposure to the rain and excessively high humidity.

References

- Lamond, A. and Hartley, J. ‘Seasoning of Timber’ Forestry Commission of New South Wales, Wood Technology and Forestry Research Division.

- CivilBlog. ‘What is Seasoning of Timber?’ http//www.civilblog.com/2017/10/12/seasoning-of-timber/ Assessed on March 6, 2018.

- Architects Academy. ‘Seasoning of Timber-2: Types of Seasoning’

Download “Seasoning of Timber”

Seasoning-of-Timber.docx – Downloaded 0 times – 1.67 MB