Introduction

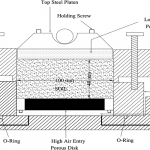

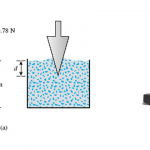

Unconfined compression test is a quick test to obtain the shear strength parameters of cohesive (fine grained) soils either in undisturbed or remolded state. It is also known as uniaxial compression test. Unconfined compression test is a special case of a triaxial test, where confining pressure is zero. This test does not require the sophisticated triaxial setup and is simpler and quicker test to perform as compared to triaxial test. In this test, a cylinder of soil without lateral support is tested to failure in simple compression, at a constant rate of strain. The compressive load per unit area required to fail the specimen is called unconfined compressive strength of the soil.

Sometimes on the field, tests like bearing capacity tests are not always possible or easy to conduct, therefore, it is cheaper to take the undisturbed soil sample and test its strength in the laboratory.

Objective(s) of the Experiment

The test is carried out to determine the unconfined compression strength of a soil sample.

Equipments and Materials Needed

- Loading frame with constant rate of movement.

- Proving ring of 0.01 kg sensitivity for soft soils; 0.05 kg for stiff soils.

- Soil trimmer

- Frictionless end plates (Perspex plate with silicon grease coating)

- Evaporating dish (Aluminum container).

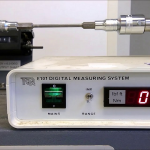

- Dial gauge (0.01 mm accuracy)

- Balance of capacity 200 g and sensitivity to weigh 0.01 g.

- Oven thermostatically controlled with interior of non-corroding material to maintain the temperature at the desired level.

- Soil sample of required dimensions (75mm length)

- Sample extractor and split sampler.

- Vernier calipers

- Dial gauge (Sensitivity 0.01mm)

Procedures

Preparation of Specimen for Testing

This test is done by testing a cylinder of soil without lateral support to failure in simple compression, at a constant rate of strain. The compressive load per unit area required to fail the specimen is determined as the unconfined compressive strength of the soil.

- Undisturbed Specimen

- Record the sample number, bore-hole number and the depth at which the sample was taken.

- Remove the protective cover (paraffin wax) from the sampling tube.

- Place the sampling tube extractor and push the plunger till a small length of sample moves out.

- Trim the projected sample using a wire saw

- Push the plunger until a 75mm long sample comes out.

- Cutout this sample carefully and hold it on the split sampler so that it does not fall.

- Take about 10 to 15 g of soil from the tube for water content determination.

- Note the container number and take the net weight of the sample and the container.

- Measure the diameter at top, middle, and bottom of the sample and find their average and record.

- Measure the length of the sample and record.

- Measure the weight of the sample and record.

- Remoulded Sample

- For the water content and dry density desired, calculate the weight of the dry soil WS required for preparing a specimen of 3.8cm diameter and 7.5cm long.

- Add required quantity of water Ww to the soil.

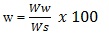

Recall that water content:

- Mix the soil thoroughly with water.

- Place the wet soil in a tight thick polythene bag in a humidity chamber and place the soil in a constant volume mould, having an internal height of 7.5cm and internal diameter of 3.8cm.

- After 24 hours take the soil from the humidity chamber and place the soil in a constant volume mould having dimensions equivalent to selected dimension of the sample (internal height of 7.5cm and internal diameter of 3.8cm).

- Place the lubricated mould with plungers in position in the load frame.

- Apply the compressive load till the specimen is compacted to a height of 7.5cm.

- Eject the specimen from the constant volume mould.

- Record the correct height, weight and diameter of the specimen.

Test Procedure

- Take two frictionless bearing plates of diameter 75mm.

- Place the specimen on the base plate of the load frame (sandwiched between the end plates).

- Place a hardened steel ball on the bearing plate.

- Adjust the center line of the specimen such that the proving ring and the steel ball are in the same line.

- Fix a dial gauge to measure the vertical compression of the specimen.

- Adjust the gear position on the load frame to give suitable vertical displacement.

- Start applying the load and record the readings of the proving ring dial and compression dial for every 5 mm compression.

- Continue loading till failure is complete

- Draw the sketch of the failure pattern in the specimen.

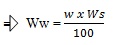

Readings and ResultsObservation and Reading

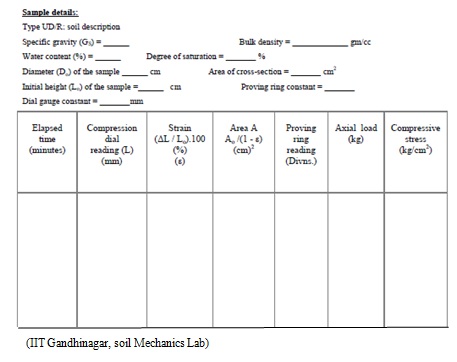

The proving ring reading is recorded in a sheet as the sample shown below

Data Analysis

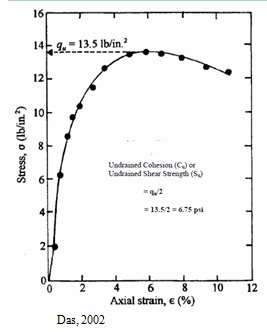

An example of stress vs strain plot is shown below (In US Customary units)

Calculations, Interpretations, and Reporting

- Axial stress = (Proving ring reading x Proving ring constant) / Acorr

- Acorr= A0 / (1-ε)

Where

A0 is the initial cross-sectional area of the soil specimen,

ε is the axial strain at that point of loading. - Maximum axial stress is obtained, which is also considered to be the failure point of the specimen.

- Repeat the test 3 times. Find the average value of maximum axial stress obtained in all three UC tests.

- Unconfined compression strength of the soil, qu = average value of maximum axial stress of three tests

- Shear strength of the soil (cohesion, c) = qu / 2

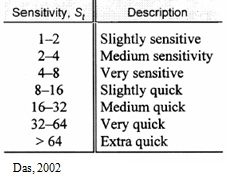

- Sensitivity St = (qu for undisturbed sample) / (qu for remoulded sample).

Discussion

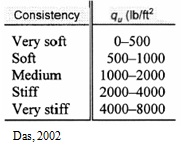

- The relative consistency is a function of unconfined compressive strength as shown in the table below:

- The sensitivity helps in the description of the soil as shown in the table below:

General Remarks

- A minimum of three samples should be tested; correlation can be made between unconfined strength and field SPT value.

- Up to 6% strain the readings may be taken at every 30 sec

- UC test is recommended for cohesive soils, or soil which can stand without lateral support.

References

- ‘Unconfined Compression Test’. Indian Institute of Technology Gandhinagar, Department of Civil Engineering, Soil Mechanics Laboratory.

- Braja M. Das (2002) ‘Soil Mechanics Laboratory Manual’, Sixth Edition, Oxford University Press.

- ‘Unconfined Compression Strength Test’. University of Texas at Arlington Geotechnical Engineering Laboratory.

- ‘Unconfined Compression Strength’. CVE407 Lecture Material, Obafemi Awolowo University, Ile-Ife.

Download “Unconfined Compression Test”

Unconfined-Compression-Test.docx – Downloaded 0 times – 374.60 KB