Introduction

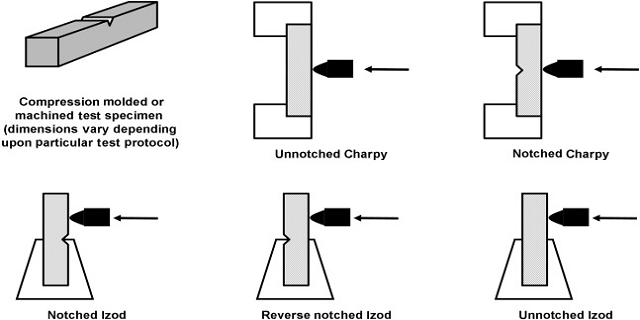

The Izod impact test was named after English engineer Edwin Gilbert Izod, who first described the test method in 1903. An impact test signifies toughness of material that is ability of material to absorb energy during plastic deformation. Impact test reveals the susceptibility of a metal to brittle fracture. Toughness takes into account both the strength and ductility of the material. Several engineering materials have to withstand impact or suddenly applied loads while in service. Impact strengths are generally lower as compared to strengths achieved under slowly applied loads. Of all types of impact tests, the notch bar tests are most extensively used. Therefore, the impact test measures the energy necessary to fracture a standard notch bar by applying an impulse load. The test measures the notch toughness of material under shock loading. Values obtained from these tests are not of much utility to design problems directly and are highly arbitrary. Still it is important to note that it provides a good way of comparing toughness of various materials or toughness of the same material under different condition. This test can also be used to assess the ductile brittle transition temperature of the material occurring due to lowering of temperature.

Click Here to go to Charpy Method

Objective(s) of the Experiment

This test is carried out to determine the energy absorbed in breaking notched steel specimens using the Izod test. The energy value is a measure of toughness of the material.

Equipments Needed

- Standard Izod Test specimens

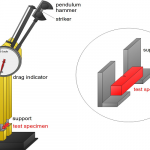

- Impact tester

Procedures

- Position the striking hammer (pendulum) in safe test position, firmly hold the steel specimen in impact testing machine’s vice in such a way that the notch face of the hammer is half inside and half above the top surface of the vice.

- Bring the striking hammer to its top most striking position unless it is already there, and lock it at that position.

- Bring indicator of the machine to zero, or follow the instructions of the operating manual supplied with the machine.

- Release the hammer. It will fall due to gravity and break the specimen through its momentum, the total energy is not absorbed by the specimen. Then it continues to swing. At its topmost height after breaking the specimen, the indicator stops moving, while the pendulum falls back. Note the indicator at that topmost final position.

- Again bring back the hammer to its idle position and back.

Results and Reports

- Impact value of – Mild Steel = _____________N-m

- Impact value of – Brass = _____________N-m

- Impact value of – Aluminum = _____________N-m

Precaution

- Measure the dimensions of the specimen carefully.

- Hold the specimen firmly.

- Note down readings carefully.

References

- Metals Handbook, 9th ed., Mechanical Testing, Vol. 8, 1990.

- G. Dieter, Mechanical Metallurgy, SI ed., Mc Graw Hill, 1986.

- N. Dowling, Mechanical Behavior of Materials, Prentice Hall, 1993.

- Mamlouk, M.S. And Zaniewski J.P., Materials For Civil and Construction Engineers, 2011

- Wikipedia

Download “Impact Test on Steel (Izod Method)”

Impact-Test-on-Steel-Izod.docx – Downloaded 0 times – 21.11 KB